The malting industry takes a great deal of care to ensure that the malts it produces are entirely safe. Pesticides and other plant protection products used in British agriculture are subject to stringent legislation under UK and EU law. In addition to these statutory requirements, plant protection products are subject to a testing regime, organised jointly by the British Beer and Pub Association (BBPA) and the MAGB, to check for any adverse effects on malt or beer quality or other effects on processing before they are accepted for use on malting barley in the UK. The results of these tests are publicised to growers and users of malting barley via the BBPA/CBRI Accepted Agrochemicals List.

Maltsters have provided a Q&A sheet on the use of Glyphosate to help alleviate concerns for malting barley.

During the growing season, various agrochemical sprays may be used to ensure a high quality, food safe crop. After harvest, malting barley may be stored for more than a year before use. Spoilage by insect or mite infestation or by mould growth are hazards which need to be controlled to minimise risk. As well as being unhygienic, insects can damage the embryo of the grain and can facilitate mould growth which is itself undesirable. A limited number of protection products are authorised for use on stored grain, to be used as part of the management strategy to protect the grain quality and safety.

Member companies of the Maltsters’ Association of Great Britain regularly monitor their barleys for residual protection products resulting from good agricultural and storage practices. These exercises have consistently demonstrated that all residues are well below any legal limits, with the majority of samples containing no detectable residues.

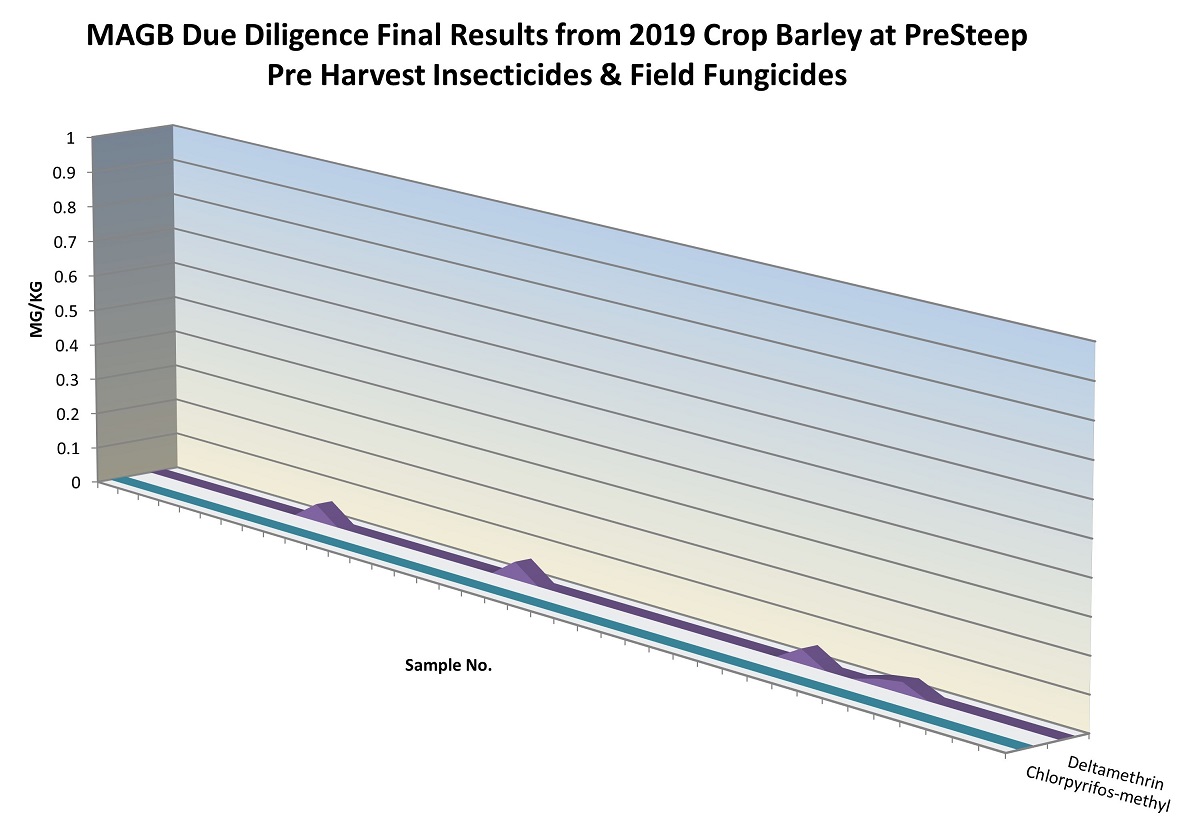

The following charts show results for residues of pre harvest insecticides & field fungicides in UK malting barleys from 2019 crop tested at intake and again at Pre Steep.

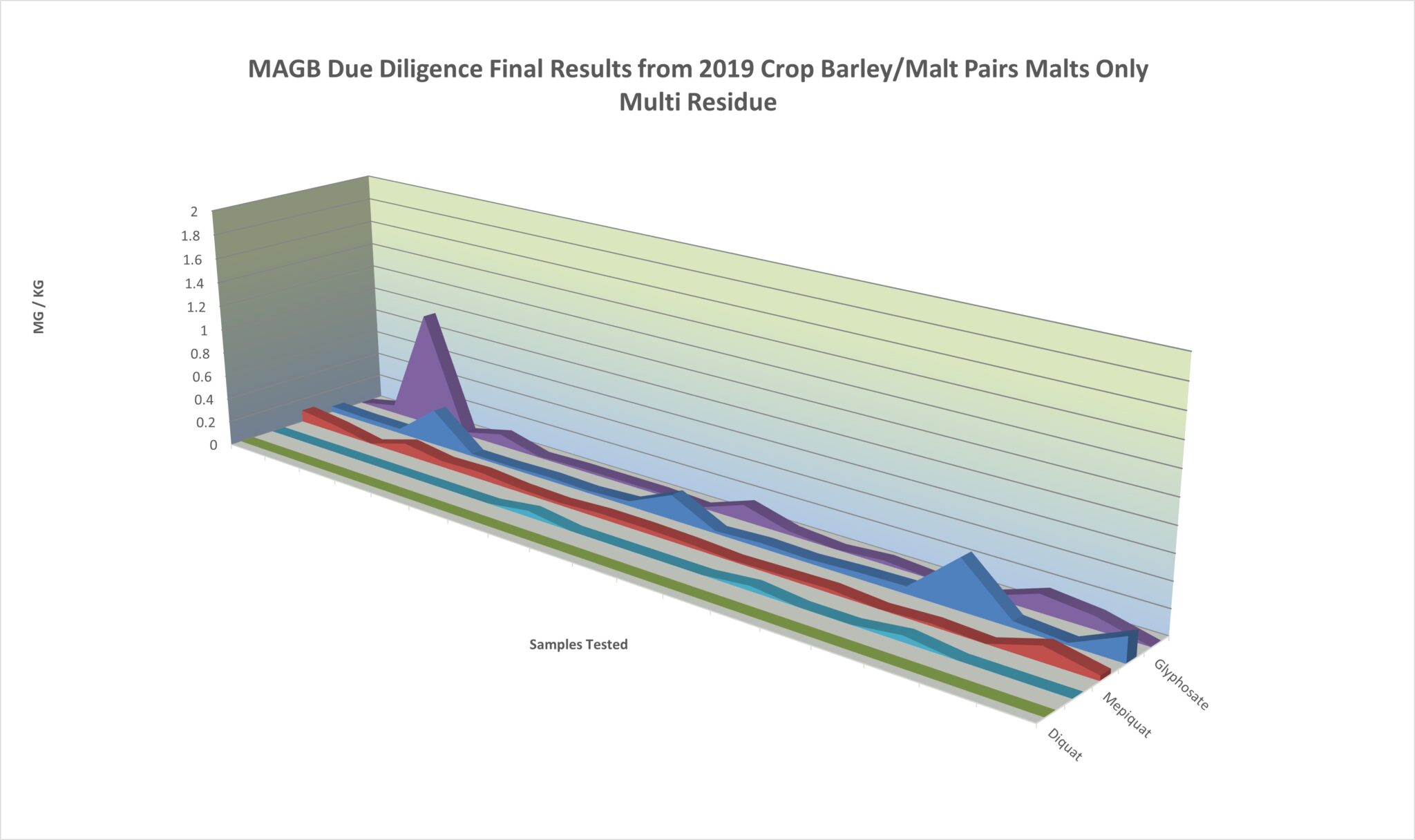

The following charts show results for glyphosate, chlormequat, mepiquat and Diquat carried out on UK malting barleys from 2019 crop tested at intake and again at pre-steep.

During malting a substantial proportion of chemical residues are washed from the grain by the steep water or are destroyed during the kilning process. Residues in malts are therefore significantly lower in malts than in barleys. This is confirmed by regular surveillance of commercial malts.

The collaborative work undertaken by UK maltsters ensures that the sector is confident in the quality and food safety of the whole UK crop. Additionally and importantly, customers worldwide can be confident in using UK malts as part of their food safety and quality management schemes.